Mechanical Engineering

About the Department

Right from the establishment of SVIT, Mechanical department was started in 1997 with intake of 60 students. Mechanical department is well equipped with workshop and laboratories. Now we have intake of 120 students in B.E. Mechanical since 2010. We also have Post graduation in mechanical CAD/CAM branch since 2010 with intake of 18 students, also Minor course in 3D printing starting year 2021 .

Discipline scales the newer heights every year because of its qualified and eminent faculty members and skilled supporting staff. By organizing various extra and co-curricular events; departments have contributed in generation of technologically skilled human force in the national integrity. Number of research publications is observed in diversified domains by our eminent faculty members. The departments are well known for their excellent performance across the country.

The undergraduate program, B.E., in Mechanical Engineering is accredited by the National Board of Accreditation, NBA, New Delhi for three years, 2023-24 to 2025-26.

Vision

To prepare technically sound and competent mechanical engineering to cater to the needs of industry and professional world.

Mission

-

To adopt outcome based education so that engineers with desired attributed are produced.

-

To bridge the gap between academics and field practices.

To nature creativity and sensitize innovations so as to enable the gradutes to implement appropriate and sustainable technologies for solving problems of the society

-

To continuously upgrade the department, faculty and students with recent trends.

PEO

-

Apply fundamental knowledge of mechanical engineering for problem solving.

-

Have attitude for teamwork and serve the industry, academia and research organizations.

-

Possess professionalism and entrepreneurial skills.

-

Demonstrate a sense of responsibility towards the need of society, nation and environment

PSO

-

Achieve excellence in product design, thermal engineering and manufacturing process using mechanical engineering concept and modern tools.

-

Ability to identify, formulate, analyse and solve various engineering problems.

PO

Engineering knowledge:

Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

Problem analysis:

Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

Design/development of solutions:

Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

Conduct investigations of complex problems:

Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

Modern tool usage:

Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations

The engineer and society:

Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

Environment and sustainability:

Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

Ethics:

Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

Individual and team work:

Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

Communication:

Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

Project management and finance:

Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

Life-long learning:

Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Programmes Offered by Department

| About | Specialization | Year of Starting | Intake | Duration |

|---|---|---|---|---|

| B.E. | Mechanical Engineering | 1997 | 120 | 4 years |

| M.E. | CAD/CAM | 2010 | 18 | 2 years |

| Minor course in 3D printing | 2021 | 3 years |

Infrastructure

AUTOMOBILE ENGINEERING LAB

This lab is use for Mechanical engineering students with facilities for the group of 30 students to carry out experiments. The lab is well-equipped and enables students to understand the fundamentals of Automotive Engineering which includes basic structure, body style, and wheel & tyre assembly. Major Equipment in Automobile Engineering Lab are: - Cut sectional chassis of Ambassador car, cut section four stroke four-cylinder petrol engine, fuel injection system, steering gear unit, Chassis of an automobile, synchromesh gear box, Hydraulic and Mechanical brake.

BME Lab

Basic Mechanical Engineering Laboratory has various Boiler Models like Cocharan Boiler, Babcock Wilcox Boiler and Lancashire Boiler and Various models of Accessories for understanding working principle of Steam Boiler. We have a model of Refrigerator to understand the VCRS cycle and various components of VCRS system. We have also a model of different couplings and gears to understand the function and application of each. In our Laboratory we have a models of a 2- stroke and 4-stroke petrol and diesel Engine to understand the various components of IC Engine and working of IC Engine.

Computer Aided Manufacturing lab

The laboratory was established by a Mechanical Engineering Department to provide our students with knowledge and hands-on experience in the area of Computer Aided Manufacturing and considering the emerging research and development in the area of manufacturing segment in the industrial fraternity. The objective of the CAM laboratory is to prepare the students industry ready and to acquire employability skills with the know of how the CNC programming and cutting tool path generation through CNC simulation software by using G-Codes and M-codes. In addition, it is aimed at to demonstrate and understand the importance of automation and its predominant role in the assembly line of shop floor, so that to satisfy the need of agil e manufacturing to meet the urging need of global competitiveness of upcoming industries. On completion of this simulation through CNC software, students will have the knowledge of key manufacturing technologies and their underlying principles applied in current manufacturing industry and will be comfortable with using commercial CAM systems to solve real world problems. Also, students are expected to develop the ability to work in industrial environment to design programs for various models and various (multi-axis) CNC machine tools. Our laboratory functioning with the following equipments. CAM laboratory comprise of following computer tools, machines, and setups: 1. CNC Milling Machine and 2. A set of Four axis Dobot Magician Robot 3. Dell makes Computers (13 nos.) 4. A Compressor 1.CNC Machining Center This CNC Milling machine with an optional 6 station Automatic Tool Changer and this machine can be compatible with Fanuc control system., Model: MTAB XLMILL, Features: PC-based 3 axis continuous path control system, 6 station programmable ATC, Programmable Spindle, Fully enclosed working area, Hydro-pneumatic vice, FMS / CIM Compatible, 2. A set of 4 - Axis Dobot Magician Robotic Arm This is a modular 4 axis articulated robot, which consists of medium duty stepper motors for all joint actuation. The controller consists of easy plug and play type cable for swift interfacing and online programming through dedicated software for various applications. Programming and control of the articulated robot for various applications both through manual as well as auto mode for repetitive tasks. The robotic arm can also be operated by Bluetooth module, WIFI module and Joystick control kit. The Dobot Magician Robot is also equipped with the Belt Conveyor, Linear Rail system, and the Vision System. The students can also learn the graphical programming (Blockly- developed by a Google) and perform the various tasks. Dobot Magician Features: Number of axis: 4, Payload: 500g, Maximum Reach: 320 mm, Position Repeatability: 0.2 mm, Controller: Dobot Integrated Controller, Path type: Point to point, linear and circular interpolation path, End effectors: 3-D Printer Kit, Laser Engraving, Pen Holder for drawing and Writing, Vacuum Suction cup, and Mechanical Gripper.

Control Engineering Lab

The feedback automatic control systems are an essential feature of numerous industrial processes, scientific instruments and even commercial, social and management situations. A thorough understanding of the elementary principles of this all embracing technology is of great relevance for all engineers and scientists. Hydraulic and Pneumatic systems are often integrated with control system. This lab gives hands on experience of various hydraulic and pneumatic circuits. Facility: Hardware Hydraulic Trainer with different types of DCVs, Solenoid Valve, Flow Control Valves. Pneumatic Trainer with compressor, Flow Control Valve, Shuttle Valve, different DCVs. Software Hydraulic Simulation Software by Festo Controls Pvt. Ltd. (15 Licenses) Subjects: Control Engineering and Oil Hydraulics and Pneumatics

Dynamics of Machines Lab

Dynamics of Machines laboratory, also known as DOM lab is associated with UG subjects such as Theory of Machines, Dynamics of Machinery and Theory of Vibration (Aeronautical Engg.). All equipment here are in running conditions and all the practical of the syllabus and beyond syllabus are performed. The laboratory has display models, apparatus, instruments and equipment. Major of them are Gyroscope, Universal Governor setup, Whirling of shafts setup, Cam analysis setup, Vib-lab frames, stroboscope and vibrometer. Our department has received a grant of Rs. 15 Lacs from AICTE for Dynamic Balancing Machine. The Machine will be installed and commissioned soon.

Fluid Power Engineering Lab

Fluid Power Engineering Laboratory is equipped with Pelton Turbine, Francis Turbine, Reciprocating Pump, Centrifugal Pump, Gear Pump, Reciprocating Air Compressor, Impact of Jet Set Up, Axial Flow Fan & Centrifugal Blower to conduct various Performance Test for practical verification of theoretical principles of fluid machines , to find out various performance parameters of fluid machines & to get performance characteristics of different machines . These equipments are useful to conduct experiments at under graduate level as well as for post level student projects.

Heat Transfer Lab

The Heat Transfer laboratory is equipped with setups that study both basic as well as applied heat transfer phenomena targeted for undergraduate heat transfer courses. This laboratory provides fundamental and industrial knowledge about modes of heat transfer, like conduction, convection and radiation, and their application. It gives the in-hand experience of lab-scale experiments on various types of equipments such as heat transfer through forced and natural convection, composite wall, pin fin, lagged pipe, emissivity apparatus, shell and tube heat exchanger, double pipe heat exchanger, dropwise and filmwise condensation, unsteady state heat transfer, etc. The lab aims to provide practical knowledge of experimental methods and it is expected that students will be able to plan an appropriate approach to experiment work, demonstrate safe working in the choice of method and apparatus and collect information to arrive at a final conclusion.

Internal Combustion Engine

An Internal Combustion Engine converts chemical energy into mechanical work to run different systems of vehicle. Aim behind this laboratory work is to teach student about basic laws of thermodynamics, heat transfer between various systems and conversion of heat to one form to another form. Students can enhance their knowledge by applying theoretical principle to practical skills. A range of different engines and fuels make students eager to brush their knowledge. After learning, students can understand difference between working of SI and CI engines, evaluate parameters of emissions and understand performance parameters of different engines. The setup consists of 4-stroke, multi-cylinders petrol (MPFI) engine connected to hydraulic dynamometer for engine loading. The setup has stand-alone type independent panel box consisting of air box, fuel tank, manometer, fuel measuring unit, and digital temperature indicator. The setup enables study of engine for brake power, BMEP, brake thermal efficiency, volumetric efficiency, specific fuel consumption, air-fuel ratio and heat balance. Provision is also made for conducting Morse test.

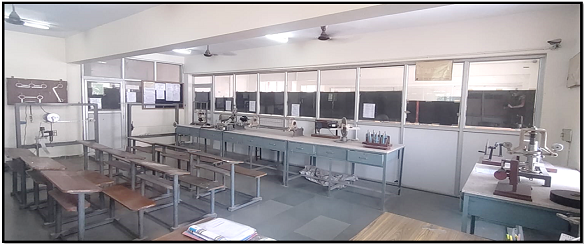

Mechanical Measurements and Metrology Lab

Metrology is the science of measurement. It is a way through which manufacturers ensure all components parts fit and work correctly. It is essential for solving almost all technical problems in the field of engineering in general, and in production engineering and experimental design in particular. Due to latest advancements in manufacturing techniques, higher productivity and accuracy cannot be achieved unless the science of metrology is properly understood. Therefore, metrology allows engineers to produce products more accurately, more quickly and to a higher standard. The aim of the Mechanical Measurement and Metrology lab is to educate students about the science of measurements. It provides a means of assessing the suitability of measuring instruments, their calibration, and the quality control of manufactured products. By having relevant knowledge in the area of Measurement and Metrology students will have firm foundation for the pursuit of graduate studies in engineering.

MATERIALS SCIENCE AND METALLURGY LAB

Materials are backbone of every industry. Understanding the basics of material science and metallurgy is absolutely vital for every engineers. Mechanical engineers mostly use metals and alloys as the basic inputs materials and are mainly concerned about their mechanical properties. Properties of the metals and alloys are dependent on the internal structure of the metals, chemical composition, shaping history and heat treatment. Therefore, by studying Materials Science and Metallurgy one can co-relate the behavior of the metals and alloys with its structure and properties. The aim of the Material Science and Metallurgy lab is to give a practical insight to the students regarding the use of basic principles of science to study the structure-properties relationships of various materials. Students are taught about various Non-Destructive Testing (NDT) methods, heat treatment methods and are given sufficient hands-on practice.

Rapid Prototyping Lab

Rapid Prototyping is a department facility created in year 2014. The facility is extensively used by students and faculty across the entire institute. The term rapid prototyping (RP) refers to a class of technologies that can automatically construct physical models from Computer-Aided Design (CAD) data. These “three dimensional printers” allow designers to quickly create tangible physical prototypes of their designs, rather than just two-dimensional pictures. Rapid prototyping machine installed at the laboratory works of Fused Deposition modelling Method. The process uses polymer filament (PLA and ABS) as a raw material to build artifacts irrespective of their complexity.

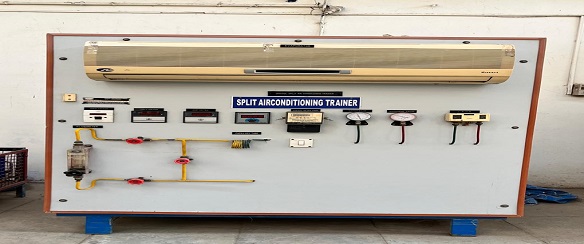

Refrigeration and Air-conditioning Lab

The Refrigeration & Air-conditioning Laboratory of this department is equipped with various experiment setups for the Under Graduate Mechanical Engineering Students. Fundamental concepts and experimental exposure about refrigeration and air conditioning systems are provided in laboratory. Ice Plant Trainer: In Ice Plant trainer students get hands on experience on the working of an actual Ice manufacturing plant. This experiment will help students understand how to prepare brine refrigerant and different components of the ice plant systems.Cold Storage Plant: In Cold storage Plant trainer setup enables students to get a hand on experience on the working of an actual cold storage plant. This experiment will help students understand the effect of the various parameters like refrigeration load, refrigerant mass flow rate, condenser cooling rate, etc. on the working cycle. Cascade Refrigeration Trainer: This Refrigerator Works on working principle of simple Vapour Compression cycle. It continuously circulating, evaporating, and condensing a fixed supply of refrigerant in a closed system accomplishes mechanical refrigeration. Evaporating occurs at a low temperature and low pressure while condensation occurs at a high temperature and pressure. This experiment will help students to understand the compounding systems using different refrigerant in each cycle of the cascade.

CAD LABORATORY

The CAD laboratory at Sardar Vallabhbhai Patel Institute of Technology (formerly known as SVIT, Vasad) is a central facility available with the Department of Mechanical Engineering, wherein all the students of the UG & PG research scholars and faculty can work with 2-D and 3-D design and analysis packages. The users are encouraged to learn, practice and apply the knowledge gained into their research areas. Initially this facility is introduced mainly for students to evolve concepts and convert it into a complete product The CAD lab provides digitally integrated environment where the users can perform: Geometric Modeling ,Finite Element Analysis ,Product Development ,Rapid Prototyping.

WORKSHOP

The workshop is a central facility which is used in first year by students of all branches. It supports teaching activities by providing demonstrations of various hand tools and machine tools used in various manufacturing processes. Students of almost all faculties of engineering uses the facilities in workshop to prepare working models in their project work. The workshop at SVIT is equipped with various shops like Fitting shop, Carpentry shop, Welding shop, Machine shop, Foundry shop, Smithy shop, Sheetmetal shop. The workshop is also equipped with state of the art machine tools like Lathe, Milling, Shaping, Slotting, Cylindrical Grinder, Surface Grinder, Power Press, Submerged Arc Welding, Tungsten Inert Gas Welding, Gas Metal Arc Welding, Shielded Metal Arc Welding, Spot Welding, Pit furnace, Single spindle automat, Electro Discharge Machine.

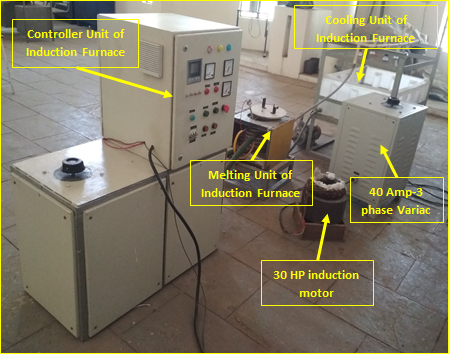

Surface Engineering

Inauguration of Surface Engineering and Nanotechnology Lab was done on 17th June 2022, by Shri Ronakbhai Patel (Chairman, NEST), Shri Alpeshbhai Patel (Treasurer, NEST) and Shri Dineshbhai Patel (Campus Director, SVIT). The occasion was graced by Dr. S.D. Toliwal (Principal, SVIT), Dr. P.V. Ramana (HOD, Mech. Engg.) and other staff members of SVIT familiy. Surface Engineering and Nanotechnology Lab is developed by Dr. Sekar Prakash Saladi, Associate Professor, Mech. Engg. Dept. and Prof. Hetal R Chauhan, Assistant Professor, Mech. Engg. Dept., with the help of research grant for Rs. 49.5 Lakhs received from GUJCOST, DST, Government of Gujarat. High Temperature Wear, Erosion and Corrosion studies can be performed as per American Society for Testing Materials (ASTM) in this laboratory. Major Facilities are: 1. High Temperature Modular Tribometer (POD 4.0, Up to 1000 C) 2. Advanced micro balance for precision weight measurements (up to 0.01 mg) 3. High Temperature Furnace for Corrosion Testing (up to 1200 C) 4. Air Jet Erosion Test Rig as per ASTM Standards

Machine tool

The machine tool laboratory is a dedicated facility for carrying out hands on practical on non conventional marching process of Electro discharge machining(EDM). the laboratory is equipped with a die sink EDM machine which is utilized for evaluating the various response parameters such as surface roughness, Material removal rate etc.

Renewable Energy engineering

Solar PV Training and Research system is a compact miniaturized version of an actual Solar PV standalone power plant. The system enables user to study wiring and interconnections of different components involved in the system to develop basic understanding of working and operation of a Standalone PV system. Through the help of experiments a student can understand underlying principles of solar PV, its applications in standalone system and challenges like sizing of system, MPPT, installations etc. by doing various experiments. The system also provides scope for further research.

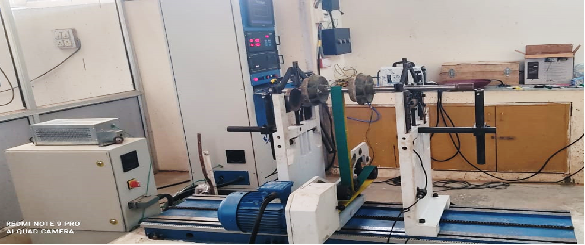

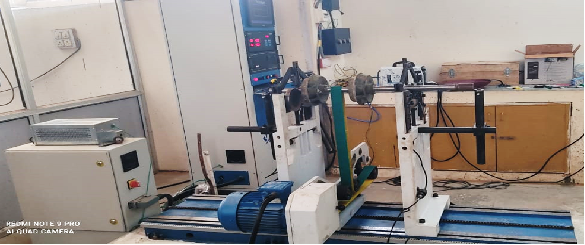

Dynamic balancing machine( MODROB Scheme)

Model: H-100, having capacity of balancing rotor of weight upto 1 tone, was purchased from ABRO Technologies Pvt. Ltd., New Delhi with the fund obtained from MODROB scheme A dynamic balancing machine is an advanced device used to measure and correct the imbalances present in rotating machinery components, such as rotors, shafts, and turbines. It employs sophisticated sensors and software to identify the specific areas where the imbalance exists. By rotating the component at high speeds, the machine can detect the areas that deviate from equilibrium, thereby enabling precise adjustments to be made. These adjustments are typically executed by adding weight to or removing weight from the component to counteract the imbalance. Balancing ensures that the rotating machinery operates smoothly, reducing wear and tear on the equipment, minimizing vibrations, and extending its overall lifespan. Dynamic balancing machines play a crucial role in industries such as manufacturing, automotive, aerospace, and power generation, where precise and stable operation of rotating machinery is essential.

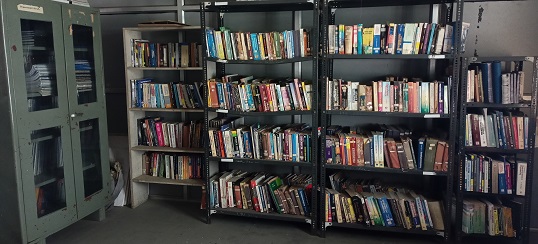

Department library

A mechanical department library is a specialized library within an academic institution that caters specifically to the needs of the mechanical engineering department. It provides a collection of books, journals, and resources relevant to mechanical engineering, supports research and learning in the field, and offers a space for students and faculty to study and collaborate. The library typically has expert staff who can assist with subject-specific inquiries and may offer access to digital resources and special collections related to mechanical engineering. DEPARTMENT LIBRARY DETAILS Books: • Titles: 312 Nos., Volumes: 392 Nos., Bound volumes of Magazines-Volumes: 85 Nos. , Proceedings of seminar / STTP/ conference / Ref. course-• Hard volumes: 22 Nos., CDs: 69 Nos., Thesis of MTech / Ph.D.- 76 Nos. , Seminar/Project reports for UG- • Hard volume: 372 Nos. , Project reports of PG- • Titles: 48 Nos. , Seminar reports of PG- Titles: 76 Nos.

Expert Lecture

Expert talk of “Modernization in Refrigeration & Air Conditioning system”

06-08-2025 - 06-08-2025

Expert talk of “Emerging Technologies and Career Pathways in HVAC&R: An ISHRAE Perspective”

06-08-2025 - 06-08-2025

Expert talk of “Modernization in Refrigeration & Air Conditioning system”

06-08-2025 - 06-08-2025

Expert talk of “Design and Manufacturing of shell and tube heat exchanger – Industry perspective” by Mr. Bhavesh Prajapati, General Manager - Engineering, The Anup engineering limited, Ahmedabad

23-03-2025 - 23-03-2025

Expert talk of “Design for Additive Manufacturing using Solidworks” by Mr. Rudresh Vyas, Head, Education at Engineering Technique for SolidWorks & 3DPrinter

07-03-2025 - 07-03-2025

Mechanical Engineering Department had organized expert talk by Mr. Amey Prakash Tattu, Lean Leader, Plant Excellence, Plasser India Private Limited,

12-09-2024 - 12-09-2024

Mechanical Engineering Department had organized expert talk by Mr. Rudra Joshi, Technical Consultant, SITECH PLM, Vadodara

10-09-2024 - 10-09-2024

Variational Technologies Pvt. Ltd., Vadodara-delivered by Mr. Kilyon Mackwan, Mr. Divyesh Chaudhry, and Mr. Devendra Dharia

29-02-2024 - 29-02-2024

Innovative Approaches in Manufacturing: Industry 4.0 Perspective

08-02-2024 - 08-02-2024

Theory and practical approach to FEA by Mr. Aaditya Shah, Design engineer, Capiq Engineering Pvt. Ltd., Vadodara

02-02-2024 - 02-02-2024

Bearing Technology and Applications by Mr. Shashank Pandya, General Manager - Business Development - Universal Sales Corporation

10-10-2023 - 10-10-2023

An expert lecture on " Basics of Solid works" delivered by Aaditya Tejas Shah, Design engineer, Capiq Engineering Private Limited, Vadodara.

16-09-2023 - 16-09-2023

Expert talk on “Surface Engineering Solutions for Modern Day Industry” by Dr. Shrikant Joshi, Professor, Division of Subtractive and Additive manufacturing, University West, Sweden

19-12-2022

Expert Lecture on "How to read manufacturing drawings" Delivered by- Prof. A. J. Shah T & P Officer SVIT Vasad

27-03-2022

Management aspects in Engineering

16-09-2021

Manufacturing Processes - An Application in Heavy Engineering Industry

11-09-2021

Career Options for Budding Engineers in Foundry Industry

10-07-2021

Expert Lecture on Welding Inspection (WPS/WPQ/PQR – ASME SEC IX) - Delivered by Dr. G.D Acharya , Principal ATIMIYA University

18-06-2021

Expert Lecture On "Fundamentals of Metallurgy" Delivered by- Dr. V.J Badheka , HOD & Professor, Mech. Engg. Dept. PDEU, Gandhinagar

18-05-2021

Expert lecture "Energy Conservation Awareness Workshop"- delivered by Mr. Prabhu Kiran And Mr. Ajinkya Gangurde Certified Energy Manager and Energy Auditor

19-02-2021

Satellite technical

17-02-2021

CFD and its Applications in Hydraulic Turbine Design

23-05-2020

Solid Modeling using solid works software

20-02-2020

Indian Space Programme: Technology Challenges in Mangalyaan, Chandrayaan and Beyond

05-02-2020

The role of CAD/CAM/CAE in industry

10-01-2020

Welding Inspection (WPS/WPQ/PQR-ASME SEC.IX)

06-01-2020

Hands on session on advanced robotics

27-09-2019

What industry expects from today’s engineers

22-08-2019

NX CAD/CAM modeling software

08-08-2019

Mechanical Systems in Process Industry

25-07-2019

Expert talk on Oil and Gas Industry

23-07-2019

Expert talk on ANSYS 19.2

20-07-2019

Expert talk on Fluid Mechanics

13-07-2019

Seminar/Workshop/Training

Two-Day Workshop on "Advances in Manufacturing & Industry 4.0" Sponsored by AICTE VAANI at Sardar Vallabhbhai Patel Institute of Technology, Vasad Coordinator, Dr. Dipen S. Shah, Co-coordinator, Prof. Priyal R. Patel

14-11-2025 - 15-11-2025

The Mechanical Department has proficiently organized a "Hands-on Workshop on 3D Scanning and Reverse Engineering."

29-02-2024 - 29-03-2024

One week Workshop on "ANSYS workbench & CFD analysis" conducted by Mr. Abhishek , Prashant singh and Mr. Ravindra Bucherla from A R K solutions, Noida, New Delhi

05-09-2022 - 10-09-2022

One day workshop on “Energy Conservation & Audit” by Dr. B. G. Desai, MD. Devki Energy Consultants, Vadodara

29-03-2022

Scope of Automotive Industry during and after COVID-19

17-07-2020

Electrical Vehicle Technology (EV)

19-06-2020

Basis of Liquid Petroleum Storage Tank and its Manufacturing

13-06-2020

Welding as Career

06-06-2020

Importance of Material Science for Engineers and Recent Advancements

05-06-2020

Opportunities for Mechanical Engineers in the field of 3D printing technologies

22-05-2020

Poster/Project Presentation

Mechanical Engineering Department of SVIT, Vasad organized presentations of sem.8 BE (Mechanical) students to review the work done by them in their Internship/Project on 13th April, 2024.

13-04-2024 - 13-04-2024

SARJAN 2021

05-06-2021

IDP/UDP Project Presentation and Evaluation

11-05-2021

IDP/UDP Project Presentation and Evaluation

30-09-2020

IDP/UDP Project Presentation and Evaluation

26-08-2020

IDP/UDP Project Presentation and Evaluation

13-05-2020

Sarjan-2019

13-04-2019

Sarjan-2018

07-04-2018

Other Activities

Grant Received by ABS-FUJITSU of Rs. 5 Lakhs by Prof. Hetal R Chauhan under the title "Development and Investigation of Thermal Sprayed Self Lubricated Coating"

01-12-2023 - 01-01-2025

Grant received from GTU MRP-RPS of Rs. 50,000 for Project Titled "Numerical and experimental investigation on tool shapes in incremental sheet forming process"

01-11-2022

Team from Sardar Vallabhbhai Patel Institute of Technology (SVIT), Vasad, comprised of 5 members won the RoboFest 2.0 as joint-winner along with SVNIT, Surat in the Rover category, and awarded with a prize money of Rs 2,50,000, during an award function held by GUJCOST, Gandhinagar.

29-10-2022

Research Grant of Rs. 850000 received for "Development of Novel Mixing Method to Prepare Nano Carbonaceous and Rare Earth Reinforced Feedstock Powders for Thermal Spray Processes"

02-08-2021

Test

11-03-2021

MOU

| Sr. No. | Company Name | MOU Date | Activities |

|---|---|---|---|

| 1 |

M G Motors, GIDC Industrial Estate, Halol, Dist. Panchamahal, Gujarat- 389351. |

23-07-2025 |

|

| 2 |

Press Stampings Industries Vadodara, Gujarat |

01-03-2024 |

|

| 3 |

Capiq Engineering Vadodara, Gujarat |

05-01-2024 |

|

| 4 |

Specialised Components Vadodara, Gujarat |

01-03-2023 |

|

| 5 |

Takalkar Power Engineers Pvt. Ltd, 419-426, Wing, Monalisha Business Centre, Near Manjalpur Railway Crossing, Manjalpur, Vadodara- 360011, Gujarat |

22-02-2023 |

|

| 6 |

Mechtech Engineers, Vadodara, Gujarat |

01-02-2023 |

Industry Visit

Industrial Visit by SY Mech at Baroda Dairy Makarpura Vadodara

03-09-2025 - 03-09-2025

Sunrise Industries, Kheda, Karjan Road, Gujarat.

19-03-2025 - 19-03-2025

M/s Steel India, Makarpura& Engineering Technique, Makarpura Vadodara

07-03-2025 - 07-03-2025

Industrial Visit at Engineering Technique Pvt. Ltd: Makarpura GIDC, Vadodara

07-03-2025 - 07-03-2025

Industrial Visit at SPRERI VV nagar

29-01-2025 - 29-09-2025

Industrial Visit by Third Year Mechanical Engg. Students at Steel India Pvt. Ltd.

08-04-2024 - 08-04-2024

Industrial Visit by Third Year students at Engineering Techniques, GIDC Makarpura, Vadodara

08-04-2024 - 08-04-2024

Industrial Visit at Capiq Engineering Pvt Ltd. Vadodara

09-03-2024 - 09-03-2024

Industrial Visit at Vexma Technologies Channi Vadodara

09-03-2024 - 09-03-2024

Industrial visit At Xylem industries Savali

05-03-2024 - 05-03-2024

Industrial visit and workshop on industrial robot programming at the International Automobile Excellence Center at Gandhinagar.

01-03-2024 - 01-03-2024

Industrial visit of Third year students at Rajnil Forging and Nodule cast GIDC makarpura

25-09-2023 - 26-09-2023

Industrial visit for Final Year students was arranged to National Level Exhibition of VCCI Expo 2023, Navlakhi Ground , Vadodara, Gujarat.

23-03-2023 - 23-03-2023

International Automobile Centre of Excellence (iACE), Gandhinagar, Gujarat

14-03-2023 - 14-03-2023

IDEAS LAB ADIT

10-03-2023 - 10-03-2023

Wanakbori Thermal Power Station, Kheda

13-10-2022 - 14-10-2022

Industrial visit for Third Year students was arranged to Shree Agro Cold Storage, Halol

01-10-2022

Growell Industries, Vadodara

27-09-2022 - 29-09-2022

Nodule Cast,Vadodara

27-09-2022 - 29-09-2022

Industrial visit for Final Year students was arranged to Sardar Patel Renewable Energy Research Institute (SPRERI) at Vallabh Vidyanagar, Gujarat

29-08-2022

Unique Airtech GIDC Makarpura, Vadodara

31-03-2022 - 01-04-2022

Unique Airtech GIDC Makarpura, Vadodara

31-03-2022 - 01-04-2022

C K Industries, Vadodara

25-02-2020

Sardar Patel Renewable Energy Research Institute (SPRERI), Vallabh Vidhyanagar

14-02-2020 - 15-02-2020

Wanakbori Thermal Power Station, Kheda

09-10-2019

IITRAM-Ahmedabad ( Centre of Excellence)

03-10-2019

Vadodara Muncipal Coorporation, Vadodara ( Water Works Department - Dodka)

24-09-2019 - 25-09-2019

"Deepa Industries,Vadodara

21-08-2019

Mahaanidhi Evaporation Pvt Ltd. Shree Agro Fresh Cold Storage, Halol

28-02-2019

Mech Tech Engineers, Vadodara Contact Person

25-02-2019 - 26-02-2019

Deepa Industries, Vadodara

25-02-2019

Shree Agro Fresh ULO Cold Storage,Khakharia Meghasar Road Ceat Tyres Road Gatemuvala, Halol Panchamahal ,Gujarat

18-02-2019 - 19-02-2019

Mech Tech Engineers, Vadodara

21-08-2018

Wanakbori Thermal Power Station, Kheda

08-08-2018

Baroda Dairy, Vadodara

25-07-2018

Achivements

12-09-2025

Tirth sharma of First Year Mechanical Engg. BADMINTON zonals GTU organised by svit vasad , 2nd rank

29-08-2025

Dr. Chetan O. Yadav, Assistant Professor in the Mechanical Engineering Department at SVIT Vasad, had the honour of serving as a Jury Member at the 23rd Internal Quality Circle (QC) Convention held at Apollo Tyres Pvt. Ltd., Limda, Vadodara29th August 2025.

14-07-2025

PATEL ANUSHA NITAL, F.Y Mechanical SPECIAL OLYMPICS BHARAT TENNIS.(BRONZE MEDAL as unified partner in Nationals) VENUE: GWALIOR, MADHYA PRADESH

09-07-2025

Arya Patel received 3rd Position, Got A Bronze Medal And certificate of participation at National Championship Tennis, Atal Bihari Vajpayee Training Centre for Disability Sports ,Gwalior ,Madhya Pradesh

22-03-2025

Ms. Ashwini Kale Received the J P Patel Memorial award for Academic Excellence in Second Year Mechanical Engg.

02-02-2024

SVIT students at MAKERS FEST Vadodara

29-10-2022

5 members won the RoboFest 2.0 as joint-winner along with SVNIT, Surat in the Rover category, and awarded with a prize money of Rs 2,50,000, during an award function held by GUJCOST, Gandhinagar

03-10-2022

Developed e-bike with Motor Specifications: Bldc, 1.5kw, 60v. Battery: Lithium ion phosphate 60.2v, 30ah

01-09-2022

Research Grant of Rs. 50,000 Received from GTU MRP-RPS "Numerical and experimental investigation on tool shapes in incremental sheet forming process"

24-08-2022

Akul Rajan Participated and received 2nd position in 1st Mixed martial art Championship held at at Vadodara

24-08-2022

Mr. Akul Rajan secured 2nd position at GTU best physic

24-08-2022

Mr. Akul Rajan secured 2nd position at GTU best physique

01-08-2022

MAN ARORA Executive Board Member Parul University Model United Nations-2022

11-04-2022

Developed Electric Car – “Eiravat” Developed by Students-Faculties-Lab technicians of Mech. & Elect. Dept. Built in a record time of one month - April-2022 Total cost of the Eiravat: 2,50,000/- Passenger Capacity: 8 + 1 Range: 80 KM (Full Charge)

23-11-2021

sahil salekar ROBOFEST-Gujarat 2.0 competition by GUJCOST received price money of 50,000/-.

20-08-2021

AKUL RAJAN 2nd Place GTU Best Physique - 2021

06-06-2021

Mr. Rajan Shah won Second Prize in all Gujarat Poster Presentation on the topic entitled “Bio Medical Waste Incinerator (Sardar Patel Renewable Energy Research Institute, Anand)

01-06-2019

Dr. D.S. Shah received Rs. 15 Lakhs from AICTE under MODROB.

21-09-2018

Mr. Abhi K Shah secured 1st Rank in M.E (CAD/CAM) in the year 2018

26-03-2016

Dr. Jitendra Mistry received Rs 3.5 Lakhs from GUJCOST

26-09-2015

Mr. Vishal Banker secured gold medal in M.E (CAD/CAM) in the year 2015

10-10-2012

Mr. Chirayu Shah secured University Gold Medal in Mechanical engg. In the year 2012